What is wind turbine blade material?

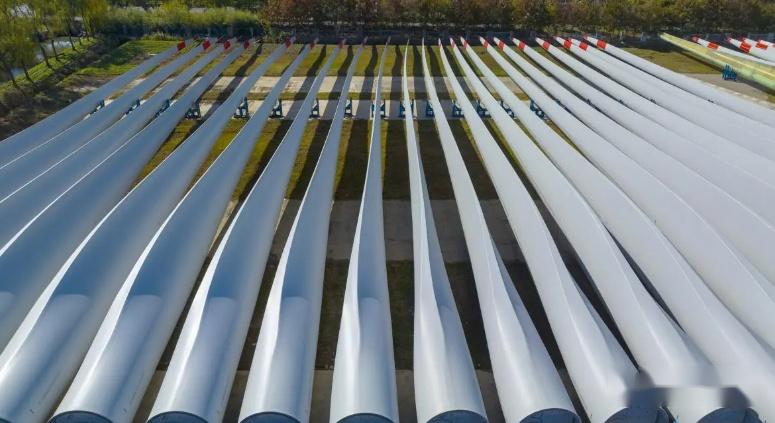

2024-12-17Wind turbine blade materials refer to various materials used to manufacture wind turbine blades, and the selection of these materials directly affects the performance, efficiency, and service life of the blades. As the core component of wind turbines, wind turbine blades are responsible for capturing wind energy and converting it into mechanical energy, which is then converted into electrical energy through generators. Therefore, the selection of blade materials is crucial.

The main types of wind turbine blade materials

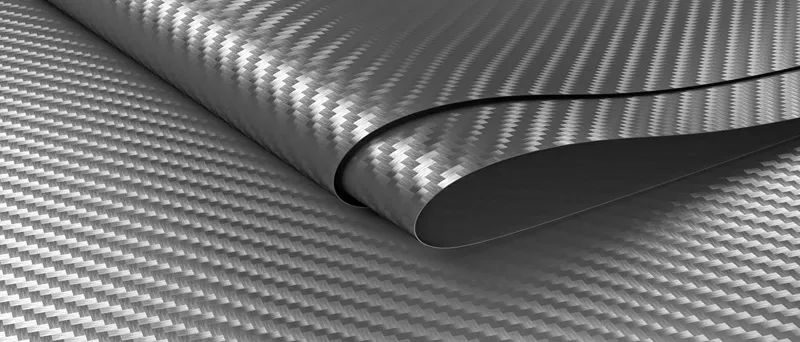

Carbon Fiber Reinforced Polymer (CFRP):

Composition: Carbon fiber composite material is composed of matrix materials such as carbon fiber and resin. Carbon fiber is a high-performance fiber with extremely high strength and stiffness, while resin serves as an adhesive to connect the fibers together and provide various other properties.

Advantages: Carbon fiber composite materials have the advantages of lightweight, high strength, high stiffness, excellent corrosion resistance, and easy processing. It can significantly reduce the weight of the blades, improve their stiffness and durability, thereby enhancing the efficiency of wind turbines.

Disadvantages: High cost, requiring higher investment costs.

Fiberglass Composite Materials (GFRP):

Composition: Fiberglass composite material is composed of matrix materials such as fiberglass and resin. Fiberglass is a commonly used reinforcing material with excellent mechanical properties and weather resistance.

Advantages: Glass fiber composite materials have relatively low costs and also possess characteristics such as corrosion resistance and ease of processing. It can be designed as needed to meet different requirements.

Disadvantages: Compared with carbon fiber, its strength and stiffness are lower, requiring more materials to achieve the same performance.

Base material:

Epoxy resin: Epoxy resin is a widely used resin in composite materials. It has good mechanical properties, chemical corrosion resistance, and dimensional stability, which is more conducive to ensuring the operational efficiency and service life of blades in harsh environments.

Unsaturated polyester resin: Unsaturated polyester resin has a wide range of raw material sources, lower cost compared to epoxy resin, and can be cured and molded at room temperature and pressure, making it easy to process.

Vinyl ester resin: Vinyl ester resin has good processability, good adhesion, stability, and excellent corrosion resistance.

Other materials:

Wood: As a traditional material for wind turbine blades, wood has also received a certain degree of attention in recent years. Wood has excellent mechanical properties and wind erosion resistance, as well as the advantage of being renewable. However, wood is prone to corrosion in humid environments, and its strength and durability cannot be compared to glass fiber reinforced plastics and carbon fiber reinforced plastics. Therefore, the application of wood in wind turbine blade materials is still limited to some extent.

Selection factors of wind turbine blade materials

Mechanical properties: The blade material needs to have high strength and stiffness to ensure that the blade will not undergo excessive deformation or damage under wind force.

Corrosion resistance and fatigue resistance: As wind turbines are usually installed outdoors and are exposed to wind, sun, and humid environments for a long time, blade materials need to be able to resist the erosion of these external environments and maintain good performance.

Density and weight: The blade material needs to have lower density and weight to reduce the quality of the blades, minimize the impact on the overall structure of the wind turbine, and improve the output efficiency of the wind turbine.

Processing and cost: As one of the key components of wind turbines, the manufacturing process and cost of blades directly affect the overall manufacturing cost and market competitiveness of wind turbines. Therefore, blade materials need to have good processing performance to ensure that the blades can be processed and manufactured through existing manufacturing processes. At the same time, the cost of blade materials also needs to be controlled within a reasonable range to ensure that the overall cost of wind turbines can be controlled.

The development trend of wind turbine blade materials

With the continuous development of wind power generation technology, wind turbine blade materials are also constantly advancing. In the future, the application of carbon fiber in wind turbine blades will become increasingly widespread, mainly manifested in the following aspects:

Improving power generation efficiency: Due to the lightweight and high-strength characteristics of carbon fiber, longer and thinner wind turbine blades can be manufactured, thereby increasing the capture of wind energy and improving power generation efficiency.

Reducing manufacturing costs: With the continuous advancement of technology and the realization of large-scale production, the price of carbon fiber will gradually decrease, providing possibilities for a wider range of applications. Meanwhile, by optimizing design and manufacturing processes, the manufacturing cost of wind turbine blades can be further reduced and their market competitiveness can be improved.

Promoting the development of green energy: As a clean and renewable energy source, wind energy will occupy an increasingly important position in the future energy structure. As one of the key materials for wind turbine blades, the application and development of carbon fiber will directly affect the prospects of wind energy development.

In summary, the selection of wind turbine blade materials is a comprehensive process that requires consideration of factors such as mechanical properties, durability, and cost. With the continuous advancement of materials science and manufacturing technology, new types of wind turbine blade materials will continue to emerge, bringing new opportunities and challenges to the development of the wind energy industry.